CIGS/CZTS

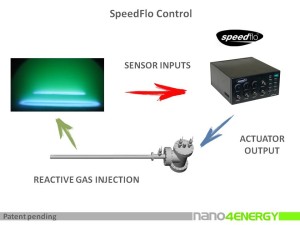

Reactive feedback control in magnetron sputtering deposition technology has increasingly been accepted in the field of high speed PVD. The introduction of suitable feedback control in certain industrial processes has made it possible to increase the deposition rates keeping an excellent degree of uniformity. This has rendered in some of the fastest return of investment seen in the deposition industry.

Feedback control in processes requiring reactive gases such as oxygen or nitrogen are relatively easy to implement via fast mass flow controllers. However, certain industrial processes require the injection and control of species that are not so easy to be delivered in a vapour phase, e.g. chalcogens used for CIGS production.

In recent years, the need for high quality and productivity CIGS for photovoltaic applications to a low cost has increased dramatically. While laboratory results have achieved efficiencies as high as 20.4%, the mass production of panels using CIGS solar cell technology has proven to be extremely difficult. The implementation of a large-scale, all-vacuum sputtering deposition process of entire CIGS cell stacks has to this day not been successfully achieved.

Regarding the development of a single-step deposition of chalcogen-based compounds, different ways to inject S or Se into the vacuum system has been presented. Some of them would involve evaporation methods where the flows of the elements are very difficult to control. In some other cases the delivery form could have severe health & safety issues, (e.g. processes involving the manipulation of H2S or H2Se).